Welcome to Comcore Optical Intelligence Website

- AC Fiber Optic Current Sensors

- AIS Unbalance Current Sensors for DC Filters and Capacitors

- AIS Unbalance Current Sensors for AC Filters

- Fiber Optic Current Sensors for DCB

- Fiber Optic Current Sensors for GIS

- Flexible Fiber Optic Current Sensors

- Fiber Optic Current Sensors for GIS

- All-Fiber Current Sensing Coils

- Integrated Current Transformer Calibration Platform

- Pulse Current Measuring Instrument

- Super-large DC Fiber Optic Current Sensors

- Lightning test system

- Comcore PFS-500 & PFS-500S Universal PM Fiber Fusion Splicer

- Comcore Universal PM Fiber Fusion Splicer

- 1x2(2x2) Compact Fused Hybrid PM Fiber Tap

- 1x2(2x2) Fused Hybrid PM Fiber Standard Tap

- 1x2(2x2) Polarization-Insensitive Fused PM Fiber Splitter (Mixer)

- 1x2 980/1064nm Fused PM Fiber Standard WDM

- 980/1035nm Single Mode Fiber WDM

- 1310/1490/1550nm Single Mode Fiber WDM Module

- 1x2 (2x2) 635/1064nm Single Mode Fiber WDM

- 1x2(2x2) Single Mode Dual-Window Broadband Splitter

- Star & Tree Single Mode Broadband Splitter Module

- High Power 1x2(2x2) Single Mode Broadband Splitter

- 1x2(2x2) 105/125µm Multi-Mode Broadband Splitter (Mixer)

- 1x2(2x2) 400/440µm Multi-Mode Broadband Splitter (Mixer)

- 1x2(2x2) 50/125µm Multi-Mode Broadband Splitter (Mixer)

- 1x3(3x3) 105/125µm Multi-Mode Broadband Splitter (Mixer)

- 1x4(4x4) 105/125µm Multi-Mode Broadband Splitter (Mixer)

- 1x4(4x4) 50/125µm Multi-Mode Broadband Splitter (Mixer)

- 14xx Four-Channel Wavelength Pump Combiner

- 14xx Three-Channel Wavelength Pump Combiner

- 14xx Two-Channel Wavelength Pump Combiner

- RGB Three-Channel Wavelength Combiner

- RB GB RG Two-Channel Wavelength Combiner

- 2x1 Multimode Pump Combiners

- 3x1 Multimode Pump Combiners

- (1+1) x1 PM Pump and Signal Combiners

- (2+1) x1 PM Pump and Signal Combiners

- (18+1) x1 PM Pump and Signal Combiners

- Nx1 High Power Laser Combiner

- 1064nm Polarization Maintaining Isolator

- Polarization-Insensitive Optical Circulator

- Polarization Maintaining Isolator

- 1064nm Polarization Maintaining Optical Circulator

- 1064nm Polarization-Insensitive Isolator

- Polarization Maintaining Isolator

- 1x2 (2x2) Plastic Fiber Splitter (Mixer)

- 1x3 (3x3) Plastic Fiber Splitter (Mixer)

- 1x4 (4x4) Plastic Fiber Splitter (Mixer)

- 1x7 (7x7) Plastic Fiber Splitter (Mixer)

- SM-MM Broadband Converter

- Thermal Expanded Single Core Fiber

- Fiber Optic Bundles

- Mode Field Adaptor

- SM Fiber Patch Cords

- Clade Power Stripper

- All-fiber current sensor flexible ring

- 1x2(2x2) Polarization-Insensitive Fused Hybrid PM Fiber Tap

- 1x3 Fused Hybrid PM Fiber Standard Tap

- 1x3 Polarization-Insensitive Fused Hybrid PM Fiber Tap

- 1x2(2x2) Mini Fused PM Fiber Splitter (Mixer)

- 1x2(2x2) 400um Fused PM Fiber Standard Splitter (Mixer)

- 1x2(2x2) Compact Fused PM Fiber Splitter (Mixer)

- 1x2(2x2) Compact Polarization-Insensitive Fused PM Fiber Splitter

- Fused PM Fiber Standard Splitter (Mixer)

- 1x2(2x2) 2000nm Fused PM Fiber Splitter (Mixer)

- 1x2(2x2) Polarization-Insensitive Fused PM Fiber Splitter (Mixer)

- 1x2 Polarization-Insensitive Fused PM Fiber Broadband Splitter

- 1x2(2x2) Polarization-Insensitive Dual-Window PM Fiber Splitter

- 1x2(2x2) Ultra-Low Ratio Fused PM Fiber Splitter (Mixer)

- 1x3 Fused PM Fiber Standard Splitter

- 1x3 Polarization-Insensitive Fused Hybrid PM Fiber Splitter

- 1x3 Polarization-Insensitive Fused PM Fiber Splitter

- 1x3 33:33:33 Fused PM Fiber Broadband Splitter

- 3x3 Fused PM Fiber Standard Splitter (Mixer)

- 3x3 Polarization-Insensitive Fused PM Fiber Splitter (Mixer)

- 1x4(2x4) & 1x8(2x8) Fused PM Fiber Splitter Module

- 125μm PM Fiber Optic Polarizer

- 80μm PM Fiber Optic Polarizer

- Fiber Optic Depolarizer

- 1x2 980/1310nm Fused PM Fiber Standard WDM

- 550nm Fused PM Fiber Standard WDM

- 1550nm Fused PM Fiber Standard WDM

- 1x2 1310/1550nm Fused PM Fiber Standard WDM

- 1480/1550nm Fused PM Fiber Standard WDM

- 532/635nm (450/532nm) Fused PM Fiber WDM

- Pization-Insensitive 980/1030nm Hybrid PM Fiber WDM

- Polarization-Insensitive 980/1030nm Fused PM Fiber WDM

- Polarization-Insensitive 980/1064nm Hybrid PM Fiber WDM

- Polarization-Insensitive 980/1064nm Fused PM Fiber WDM

- Polarization-Insensitive 980/1310nm Hybrid PM Fiber WDM

- Polarization-Insensitive 980/1310nm Fused PM Fiber WDM

- Polarization-Insensitive 980/1550nm Hybrid PM Fiber WDM

- Polarization-Insensitive 980/1550nm Fused PM Fiber WDM

- 1x1 Fused PM Fiber Attenuator

- PM Fiber Standard Combiner

- 980/1064nm Single Mode Fiber WDM

- 980/1310nm Single Mode Fiber WDM

- 1064/1310nm Single Mode Fiber WDM

- 1064/1550nm Single Mode Fiber WDM

- 1310/1490nm Single Mode Fiber WDM

- 1310/1550nm Single Mode Fiber WDM

- 1480/1550nm(1480/1590nm) Single Mode Fiber WDM

- 1550/1625nm Single Mode Fiber WDM

- 980-20 Fiber 980nm/C or L Band WDM

- 980-20 Fiber 980nm/C+L Band WDM

- 980-16 Fiber 980nm/C or L Band WDM

- 980-16 Fiber 980nm/C+L Band WDM

- Hybrid (Dissimilar) Fiber 980nm/C or L Band WDM

- 1x2(2x2) 200/220µm Multi-Mode Broadband Splitter (Mixer)

- 1x2(2x2) 62.5/125µm Multi-Mode Broadband Splitter (Mixer)

- 1x3(3x3) 50/125µm Multi-Mode Broadband Splitter (Mixer)

- 1x3(3x3) 62.5/125µm Multi-Mode Broadband Splitter (Mixer)

- 1x4(4x4) 50/125µm Multi-Mode Broadband Splitter (Mixer)

- 1x4(4x4) 62.5/125µm Multi-Mode Broadband Splitter (Mixer)

- Star & Tree 50/125µm Multi-Mode Broadband Splitter Module

- Star & Tree 62.5/125µm Multi-Mode Broadband Splitter Module

- 4x1 Multimode Pump Combiners

- 7x1 Multimode Pump Combiners

- 19x1 Multimode Pump Combiners

- (1+1) x1 Pump and Signal Combiners

- (2+1) x1 Pump and Signal Combiners

- (6+1) x1 PM Pump and Signal Combiners

- (6+1) x1 Pump and Signal Combiners

- (18+1)x1 Pump and Signal Combiners

- 4 Port 1064nm Polarization Maintaining Optical Circulator

- 4 Port Polarization-Insensitive Optical Circulator

- Polarization Maintaining Tap Isolator

- Polarization-Insensitive Isolator

- Fused Single Mode Fiber Tilt Filter

- MM Fiber Patch Cords

- 980/1310nm Single Mode Fiber WDM

- 80/165μm 980-20 Fiber 980nm/C or L Band Compact WDM

- 1310/1550nm WDM Module with High Isolation

- 1550/1625nm Single Mode Fiber WDM

- 1x2(2x2) Compact Single Mode Broadband Splitter

- 1x2(2x2) Compact Single Mode Narrowband Splitter

- 1x2 PDL-Free 50/50 Broadband Splitter

- 1x2(2x2) Single Mode Allwavelength-Broadband Splitter

- 1x2(2x2) Single Mode Broadband Splitter

- 1x2(2x2) Single Mode Narrowband Splitter

- 1x2(2x2) 405nm(450nm) Single Mode Narrowband Splitter

- 1x2(2x2) Single Mode Triple-Window Broadband Splitter

- 1x2(2x2) Single Mode Ultra-Broadband Splitter

- 1x2(2x2) 1310nm(1550nm) Single Mode Ultra-Broadband Splitter

- 1x2(2x2) 1055nm(1064nm) Single Mode Broadband Splitter

- 1x2(2x2) 850nm (830/780nm) Single Mode Broadband Splitter

- 1x2(2x2) Ultra-Low PDL Broadband Splitter

- 1x2(2x2) Ultra-Low PDL Narrowband Splitter

- 1x2(2x2) Ultra-Low Splitting Ratio Taps

- Star & Tree Single Mode Dual-Window Broadband Splitter Module

- Star & Tree Single Mode Narrowband Splitter Module

- 1x3 Single Mode Broadband Splitter

- 1x3 Single Mode Dual-window Broadband Splitter

- 1x3 Ultra-Low PDL Narrowband Splitter

- 1x3(3x3) 80μm Fiber Single Mode Narrowband Splitter

- 1x3(3x3) Single Mode Narrowband Splitter

- 1x4 Single Mode Broadband Splitter

- 1x4 Single Mode Dual-Window Broadband Splitter

- 1x4 Single Mode Narrowband Splitter

- 1x5 Single Mode Broadband Splitter

- 1x6 Single Mode Broadband Splitter

- 1x7 Single Mode Broadband Splitter

- 1x8 Single Mode Broadband Splitter

- 1x8 Single Mode Narrowband Splitter

- 2x4 Single Mode Narrowband Splitter

- 4x4 Single Mode Narrowband Splitter

- Fused SM Fiber Attenuator

- 1x2(2x2) 80μm Fiber Single Mode Narrowband Splitter

- 1x2 (2x2) Ultra-High Reliability Single Mode Narrowband Splitter

- 2x2 50/50 Single Mode Narrowband Splitter

- Star&Tree Single Mode Dual-Window Broadband Splitter Module

- 1x2(2x2) 80μm Fused PM Fiber Splitter

- 980/1550nm(980/1590nm) Single Mode Fiber WDM

- PM Fiber Patch Cords

- 1x2(2x2) Single Mode C/L Band Broadband Tap

- 1480/1550nm(1475/1558nm) Single Mode Fiber WDM

- 1x3 Single Mode Narrowband Splitter

- 1x2(2x2) Mini Single Mode Broadband Splitter

- 1310/1550nm High Temperature Single Mode Fiber WDM

- 1x2(2x2) High Temperature Single Mode Broadband Splitter

- High Power 980nm/C Band WDM

- 1x2(2x2) High Temperature Single Mode Narrowband Splitter

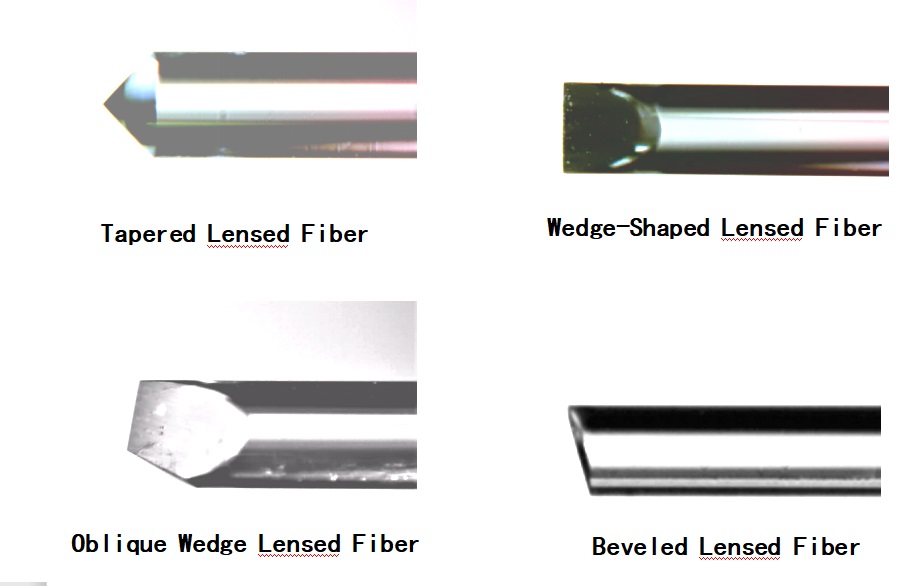

- 45° Oblique End-face Lensed Fibers

- 8° Oblique End-face Lensed Fibers

- Wedge Cylindrical Lensed Fibers

- Oblique Wedge Lensed Fibers

- Tapered Spherical Lensed Fibers

- Fused Tapered Lensed Fibers

- Long Focus Lensed Fibers

- Biconical Optical Lensed Fibers No data

Sales Tel:

+86 13901783908

+86 15721079078